Workshop

Many masters consider the presence of such a brush a relic of the past, preferring modern tools. However, a true specialist understands the real merits of such a product, and always keeps it at hand. Moreover, for some operations brushes with specific parameters of both the form itself and the bristles are needed.

Read MoreI like the old big and heavy speakers that were popular in the 90s. Despite their considerable age, they still sound pretty good and give out good bass. Recently, a couple of these speakers fell into my hands in a deplorable state, but I decided to restore them and bring them back to life. Professional repair of such speakers is very expensive, therefore, quite working equipment is often simply thrown out and bought by modern subwoofers, which are compact in size.

Read MoreWhen you do something on the desktop, good lighting is very necessary. I used a fluorescent lamp. Her light was enough for all my needs. Putting things in order in the workshop, I safely broke my backlight. It is very inconvenient to work with ceiling lighting. He made an early decision. Build a new highlight for your desktop.

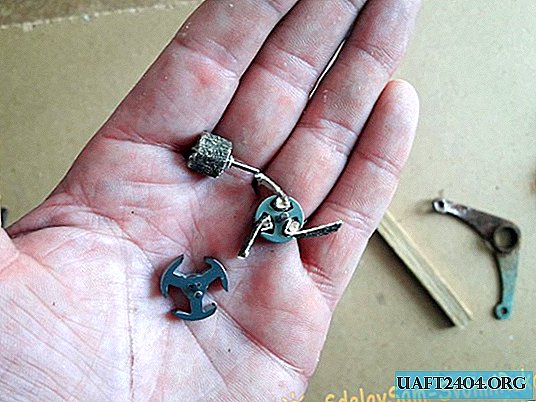

Read MoreJust a super device for quick cleaning of the workplace. We drilled, drank it, carried it with a magnetic brush, and in a couple of seconds we removed the metal chips in one motion. A very convenient and necessary thing. Collects the smallest granules, which is so difficult to achieve with a regular brush. Such a miracle is made in two counts.

Read MoreWho did not feel irritation, looking for one or another wrench in the drawer of a bench or in a special box where they are usually located in a chaotic mess? There is an opportunity not to spoil your mood, improve the culture of your work and not waste time searching for the right tool.

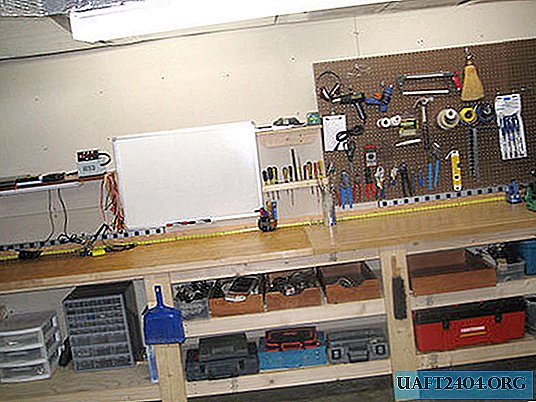

Read MoreI think, sooner or later, every master begins to annoy the lack of a normal job. So it was with me: the room reserved for the workshop was more like a warehouse or just a cluttered pantry, where the entire tool was pierced in the corners and at the same time dumped into one pile. In order to find something (and even less so), you had to spend a certain amount of time and nerves.

Read MoreWithout a metalwork vice it is impossible to imagine a car repair shop or a home workshop, regardless of what material you have to work with: metal, plastic or wood. Usually everywhere they use a classic vice with a handle that slowly clamps and unclenches the details. It is completely easy and in a short time you can make homemade metal vice with an eccentric clamp, which are compact in size, and also allow you to quickly and reliably fix the workpiece.

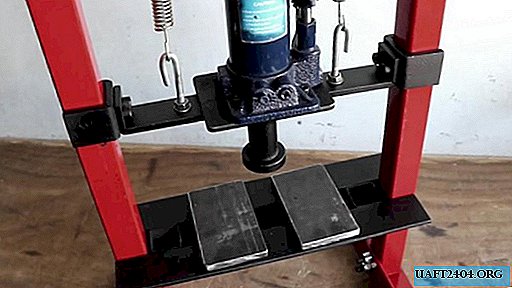

Read MoreVery simple construction of a hydraulic press from a conventional car jack. When repairing a car, motorcycle, as well as performing various types of work, it becomes necessary to use a press. With it, you can make controlled bending of parts, align them, squeeze out pressed bearings, etc.

Read MoreFull-fledged milling and circular machines are expensive and take up a lot of space in the workshop, so they are not suitable for everyone. If you equip a hand-held power tool with a special guide, then the capabilities of such equipment are greatly expanded. The proposed design allows you to work with a hand mill and a circular saw.

Read MoreWashing machines often fail, while maintaining the full efficiency of their engine. Its power and actual speed are well suited for the use of this spare part in the manufacture of home-made machines. As it turned out, such an electric drive is also an ideal solution for installation on a makeshift grinder.

Read MoreHeating of outbuildings and utility rooms is accompanied by significant additional costs, which is not suitable for everyone. However, it turns out that they can maintain a positive temperature almost for free. Of course, this is possible only under certain conditions - the presence of a gas boiler engaged in heating the house.

Read MoreExperienced craftsmen to sample the bowl (recess) in a wooden spoon, and this is perhaps the most difficult and critical operation in the manufacture of such a product, can do with a semicircular joiner's chisel. If you do not have the practice of working on wooden crafts, then manipulating such a standard tool will not be very convenient and productive.

Read MoreA flexible shaft for a drill or screwdriver, a thing used extremely rarely. However, if you need to drill a hole, or screw the screw in a hard-to-reach place where the screwdriver does not fit, this tool is best to be available. Even if the drilling site is open, but located, for example, under the ceiling, it is better and more convenient to hold the light handle of a flexible shaft on the weight than the entire drill, which weighs a lot.

Read MoreSmall 2-stroke single-cylinder low-power engines are widely used in everyday life. They are used on chainsaws and motor mowers, in motor-ice drills and gas-electric units. As well as in other models of technology. The disadvantage of these engines is their low engine life, the main source of which is the wear of the crankshaft parts onto which the main thrust bearings are pressed.

Read MoreThe most difficult, but also reliable way to create a loop (ogon) at the end of the cable is weaving. This method is better known as chalka. The technology of binding to the fire is not complicated, but it requires physical effort. You can weave any cable, the main thing is that there is enough hand power for this. In the future, at a critical load, such a loop will not open, and if a break occurs, it is definitely not on it.

Read MoreIf necessary, drill a central hole on the part that will rotate, usually using a lathe. In this case, the drill is clamped motionlessly, and the workpiece itself is pushed onto it. However, not everyone has a lathe, but every time they are reluctant to turn up to the lathe for details. To center small parts, you can make a prefix to the drilling machine from a conventional drill chuck, and perform similar work yourself.

Read MoreThe clamping force, which develops a hand screw with a lever on a conventional bench vice, reaches a value of 1000 kg to 2000 kg. Given the hardness of the jaws and the presence of notches, not only risks can remain on the workpiece, but also deformation and even breakage can occur. The probability and degree of damage is the more real, the smaller the area of the contact "spot" with jaws and the softer the material of the part.

Read MoreNot everyone has the financial ability to purchase a factory-made power-saw bench for households. But if you look around, you can find a lot of materials from which you can assemble a home-made sawmill. Perhaps there will be some costs with the purchase of an electric motor (a used, but serviceable one) and circular saws will do, but still they will be incomparably less than the cost of a factory sawmill.

Read MoreThere is such a situation when the desired tool or consumable is missing. Broke, end - no matter. And it’s good if the store where you find the necessary item is nearby. In today's master class, we will focus on grinding heads with replaceable sandpaper (or cloth).

Read MoreIf the wooden handle of your hammer or ax is broken or you decide to just upgrade it, then this workshop is for you. I found an old broken hammer and decided to restore it. It all came down to replacing his pen with a new one. The process is not complicated and accessible to everyone. It will be required. For its manufacture we will need: Hammer.

Read More