Workshop

The purchase of a factory-made belt sander is costly. Also, the industrial grinder has large dimensions and for its installation a significant area may be required. But it is possible to make this grinding machine yourself in a home workshop without the high cost and, at the same time, compact size, based on a standard grinder.

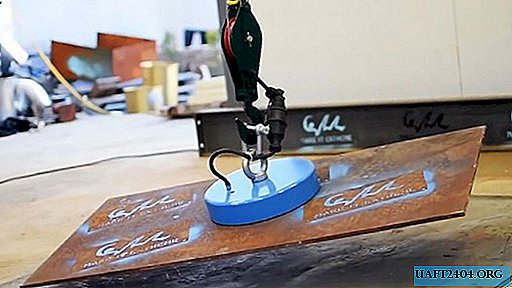

Read MoreUsing a crane beam, it is easy to move steel parts around the room: quickly and effortlessly. That's just most often these parts have a completely different shape, and fixing them with a strapping is extremely convenient, sometimes not even possible. To do this, we offer to collect a simple electromagnet from several microwaves, which are always in abundance in any landfill.

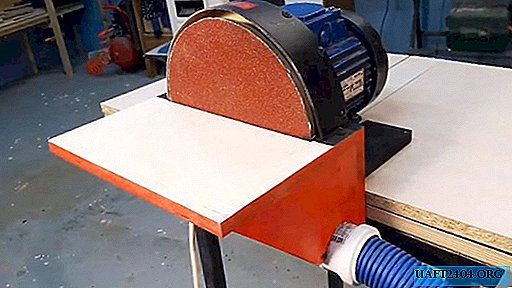

Read MoreThe disc grinder from the entire list of workshop equipment has the simplest design. In this regard, such a tool can be done independently, and the money saved can be spent on something else. A home-made grinding machine is not inferior to a factory one, and its production will take only 1 day.

Read MoreMilling machines are widely used in furniture production and, since they belong to professional equipment, are not cheap. Among them, the most versatile and widely used is the submersible (vertical or rod) milling cutter, which can be made by itself from the outdated components and parts. It will be required. To make a home-made milling cutter, we need to get: an electric motor from an old washing machine; two front shock absorbers from the "Lada"; conventional collet chuck for a drill; start button; a small sheet of thick metal; open metal profile and round tube; stud, plain nuts and wing nut.

Read MoreNot everyone can afford to buy a drilling machine in the garage for amateur use, because for self-made ones I offer my step-by-step instructions for making a wooden stand for a drill, a bonus is the possibility of processing using a grinding drum. Necessary materials: Wooden beam - 90x45 and 50x50 mm.

Read MoreThe anvil is a supporting blacksmith tool on which cold and hot processing of metals associated with plastic deformation is performed. It is not necessary to buy a small anvil; it can be made independently mainly from an old piece of a railway rail. According to GOST, the face of the anvil must be made of steel grade 45L or 35L, and it must be tempered so that the hardness is within HRC 45-50.

Read MoreSometimes there is a need to groove the outer ring of the bearing along the diameter or end. Given the high hardness of bearing steel, which cutter should be selected for this operation on a lathe? A bit of theory ... After hardening and subsequent low-temperature tempering, the hardness of bearing steel should be at least HRC 62.

Read MoreShkantovye connections are very popular among joiners, this is the only way to make the place of fixing parts completely invisible. But there is one problem - it is quite difficult to accurately center the holes for the dowels. Professionals make various devices to facilitate the process, we offer you one of them.

Read MoreEverything contributes to such a metamorphosis: metal, aspect ratio, the presence of straight or oblique teeth, etc. In short, the timing gear from a passenger car can serve as an ideal blank for making a wood end mill. We will need In addition to the mentioned gear, we will need a small segment of the steel pipe and a bolt connection commensurate with the transverse size of the mounting hole of the timing gear.

Read MoreIt is not difficult to melt tin or lead on an ordinary gas or electric stove, and even on a fire, since they begin to flow at 232 and 327 degrees Celsius, respectively. It is more difficult to do this with aluminum, which melts only at 660 degrees Celsius. No domestic heating device can provide such a temperature.

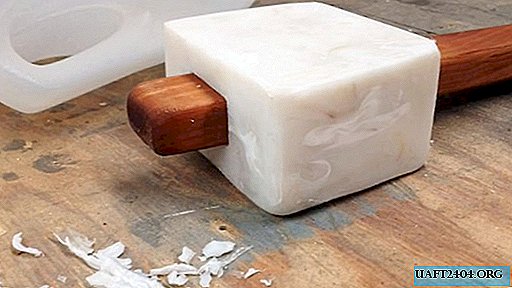

Read MoreOf the two mallets of the same size, plastic is heavier than wood. It is convenient for working with sheet metal. Therefore, roofers and tinsmiths are willing to use it, especially since it is less "noisy." For its manufacture, special skills, expensive materials and special tools are not needed.

Read MoreWithout a vice, many works will become difficult to accomplish, while others will generally remain unrealized. The price of an ordinary bench vice is from 5,000 rubles, a considerable amount. It makes sense to make them yourself, because this does not require special skills, tools and materials. You will need the basic material necessary for making a vice among the worthless rubbish: an equilateral corner; a piece of metal sheet; a small steel strip; scotch tape and writing paper.

Read MoreIn carpentry and plumbing, clamps are often used, which are compressed and extended for a sufficiently long time. Their quick-clamping analogues hold the workpieces weakly, so they are not always applicable. However, there is a design of a powerful quick-clamp clamp, which can be repeated at home. Materials: profile pipe 30x20 mm or more; strong laid on furniture loop; a protective plate with a core removed from the magnet of an acoustic speaker; bearing; a sleeve for joining the core of the speaker plate and the inner race of the bearing; sheet steel 2-4 mm; handle from grinder or drill.

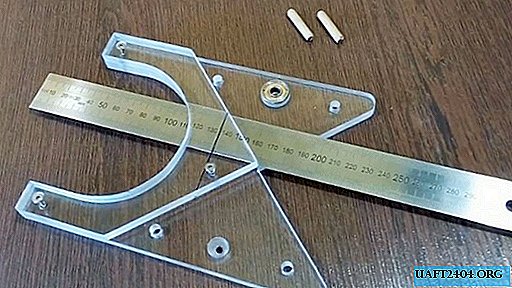

Read MoreThe volume of work and the quality of the final result depend on the accuracy of the markup. There are many factory devices for this, but they will have to pay a considerable amount. In order not to spend money, we will make a home-made markup that replaces several special ones. It will be required. For the manufacture of homemade products, we will do with simple materials and components: plexiglass; with screws 3.0 × 16 mm; bearing; round flat magnet; glue.

Read MoreSuch a home-made machine will greatly facilitate the lives of craftsmen who often have to manually saw metal with a hacksaw. What you need to have The main drive is an electric meat grinder. The machine itself is made of metal. To make it, you need a strip with a thickness of about 2 mm and a width of 1-2 cm, a metal pipe with a diameter of 0.5 inches, a length of about 50 cm, selected depending on the overall dimensions of the machine bed.

Read MoreThe convenience and versatility of this device is that an expansion table from a circular saw is used as a support for the milling table. As a result, the standard parallel emphasis can be used both for circular and for the milling cutter. In this case, the milling cutter is used to the maximum. And another plus is that in the manufacture of no changes are made either to the design of the milling cutter or to the design of the circular saw.

Read MoreWhen working with a tree, the presence of a basic set of tools is insufficient to perform the full range of possible tasks. Many things can be done only by using ingenuity, tricks and home-made appliances. Consider 6 useful secrets that can improve the quality and convenience of woodworking.

Read MoreLike any professional equipment, a milling cutter costs a lot of money. It is mainly used in the manufacture of furniture. For use at home, it can be made on the basis of a grinder (angle grinder). It will be necessary Along with the grinder we will prepare the following materials and details: drill chuck; metal rods; springs and bushings persistent; plexiglass; a strip of metal; emphasis handle made of plastic; screws, bolts, wing nuts; glue and rags.

Read MoreFor smooth, accurate bending of metal workpieces, a bending press is required. This is expensive equipment, the purchase of which is only suitable for professional activities. To solve amateur tasks, the press can be made with your own hands. However, besides him, you need to prepare a special stamp.

Read MoreUsing this universal carriage, it is convenient to cut wooden workpieces and saw them exactly to size with the help of ring stops. And with the help of simple additions, you can make a thorn-groove box connection or make decorative grilles. You will need: Plywood 12 mm thick. Thick board (40-50 mm).

Read More