Beautiful forged elements (flowers, leaves, etc.) for decorative decoration of various metal products and designs can be made with your own hands in the "cold" way, without resorting to the use of hot forging technology.

To do this, you need a 2 mm thick steel sheet and paper product templates that you want to make. Connecting individual parts to each other can be done by welding. Having mastered forging by the "cold" method, you can create unusual artistic "compositions" of metal quickly and efficiently.

The main stages of work

Using pre-prepared paper templates, it is necessary to transfer the contours of future products to the surface of a steel sheet. After that, carefully cut the workpieces with a grinder - manually this process will take much longer.

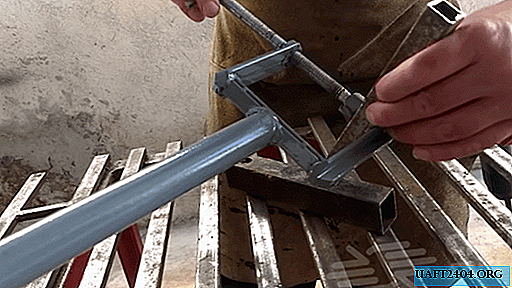

Then, the edges of the steel billets must be additionally treated with a round file to remove burrs. Next, we make markings on the surface of the parts (in accordance with the template) and with the help of a special device for cold forging you need to push the drawn lines.

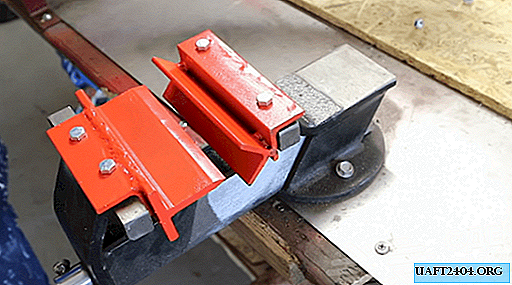

At the next stage of work, using straightening hammers, we give the workpieces the final shape, and, if necessary, modify the edges of the products with a regular file - we achieve maximum symmetry. When welding forged elements, it is better to set the welding machine at 200-220 A.

Blacksmith's hand-made products in a “cold” way look very elegant and original. Moreover, with some skill, the manufacture of forged elements does not take as much time as it might seem. For a detailed master class, see the video on our website.

Forging is a high-temperature treatment of various metals (iron, copper and its alloys, titanium, aluminum and its alloys) heated to forging temperature.