Share

Pin

Tweet

Send

Share

Send

Saw blade selection

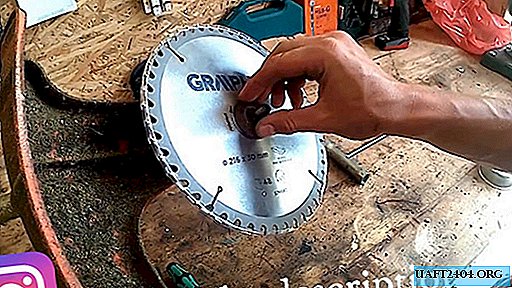

We select a TST series diamond blade designed for working with wood and multilayer plywood, with the following main characteristics:

- outer diameter along the tops of the teeth - 216 mm;

- landing hole - 30 mm;

- number of teeth - 48.

Three rings with the same outer (30 mm) but different inner diameter are included in the kit, that is, they differ in width from each other. These rings are designed to compensate for the difference between the mounting hole of the saw blade and the counter element on the pressure washer of a larger diameter.

Diamond blade installation

This operation looks no different from the attachment of a typical disk, except that it requires even more attention, accuracy and thoroughness of control.

We remove the reel with fishing line by blocking the gearbox shaft with a special pin or a screwdriver suitable for diameter, rotating the fishing container counterclockwise.

We try on a diamond disk to the lower spline washer and make sure that its seat hole is larger than the diameter of the seat belt on the washer. At high speeds, the saw blade may shift, an imbalance will occur, which will inevitably lead to breakage of the tool and even injure the operator or people nearby.

We try on alternately compensating washers and select the one that is suitable in width and completely selects the gap between the seat of the saw blade and the centering belt of the lower washer.

We install alternately on the gearbox shaft a lower washer with a compensation ring, a diamond disk, an upper washer and a protective cup, which still partially redistributes the clamping force over a large area.

We tighten the entire resulting package on the gearbox shaft with a nut with a left-hand thread, first by hand, and then with a socket wrench, blocking the gearbox shaft from below using a suitable screwdriver.

We remove the protective split plastic tube from the teeth and once again check the strength of the saw blade mounting on the gearbox shaft. If it turned out to be reliable, then the trimmer, with the diamond blade installed, is completely ready, both for traditional and not intended for this tool work.

Test in practice

For safety, it is necessary to wear a protective helmet with a transparent visor to protect the face, gloves on hands.

First, we try to remove thin dry branches, gradually moving to larger ones, and end the test by sawing down dry and semi-dry tree trunks with a diameter of 7-8 cm.

We make sure that the diamond blade trimmer works quite efficiently, reliably and safely. Slices, both transverse and oblique, are very smooth. Crumpled and torn wood fibers are not visible on them.

Mowing grass with a diamond blade is also quite comfortable, efficient and productive, regardless of its height, density and degree of dryness.

So, the trimmer with a saw blade not only perfectly performs its direct functions (mowing grass), but also expands the scope of application (removing knots and branches from trees, and sawing off thick trunks).

Attention! Do not get involved in installing saw blades of large diameter and thickness on the trimmer, as this will cause an increase in the load on the gearbox and motor, and possible premature failure. Also, the safety of such a tool will decrease, which should not be allowed in any case.

Share

Pin

Tweet

Send

Share

Send