Share

Pin

Tweet

Send

Share

Send

This method of surface restoration and rust removal is suitable for those who want to return old things from steel to their normal appearance and remove traces of corrosion.

Probably, many of you found interesting antiques from your grandmother in a closet, or when buying an old house, which were all in rust and had to be thrown out due to the inability to return to its former appearance.

This method removes rust from the surface of iron without mechanical stress. We will use electrolysis.

Of course, this method does not give a 100% guarantee of recovery, but this is the most effective way that I know.

You'll need:

Source of power

A low-voltage power supply voltage of 6-30 volts and a current of 10 amperes. I took the charger from the car. Of course, you can use sources with a lower current strength, then the time of the course of the chemical reaction will increase proportionally and take a decent time. To control the process, it is desirable that the source be equipped with an ammeter.

Plastic bath

A plastic or plastic container is a chemically resistant container. The dimensions are several times larger than the object whose surface you are going to restore. Empty containers for building paints or mixtures are well suited.

You may also need a second container for storing the solution. Unless of course you are going to store it. The properties of the solution during storage are not lost, unless it is necessary to mix it before use.

Washing soda

The main component of starting a stable chemical reaction is washing soda. Not baking, but namely soda used for washing clothes (Soda ash - sodium carbonate). Sold in stores with household chemicals.

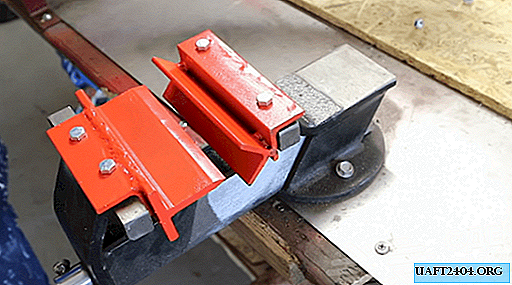

Steel for anode

For the anode, you need steel - a sheet of steel, a piece of iron, reinforcement, etc. The larger the anode area, the better and faster the chemical reaction will proceed.

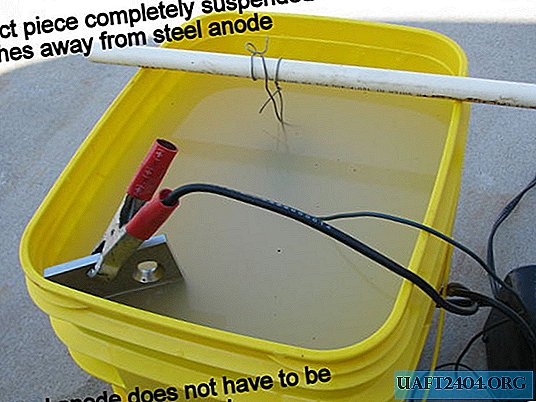

Device

A device for hanging a restored object so that all surfaces are free. Because, if you just put an object on the bottom, those parts that came into contact with the bottom will not be subject to recovery. I took a piece of plastic pipe and wire.

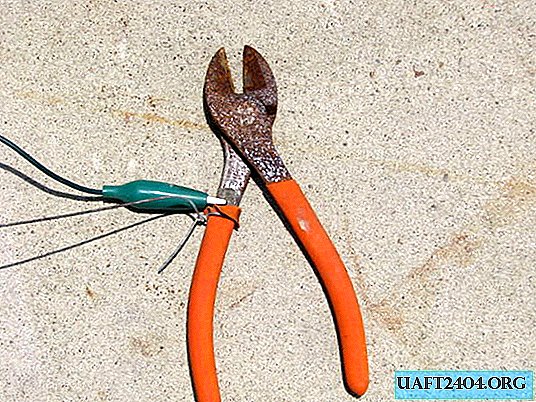

Wires

Take wires that are not a pity, so as not to spoil the wires of the car charger.

Security measures

All work only in the open. The reaction produces a large amount of hydrogen, which is extremely explosive.

Never work in a garage or other enclosed area.

The preparation plan is as follows:

- Fill the container with the required amount of water. Add soda, at the rate of 1 tablespoon per 3 liters of water. Move everything until completely dissolved. To make soda dissolve better - take hot water, if possible.

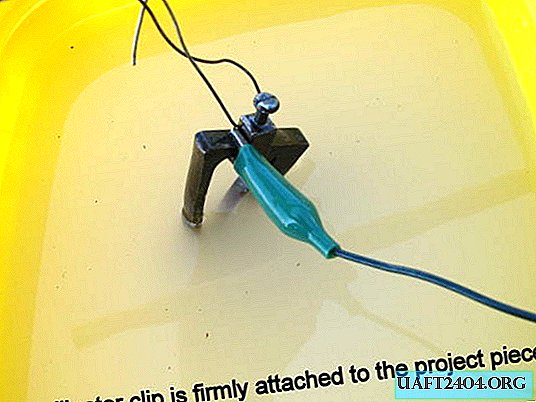

- Install the device to hang the item. Suspend an item for reconstitution in water so that it is completely immersed in the solution. Connect the negative lead of the source.

- Place the anode steel in the solution. The steel bite can not be completely immersed, but make sure it is submerged more than half. We connect the positive contact of the source to the anode. The anode should be located at a distance from the cathode, preferably on the sides of the vessel.

If the cathode and anode are too close, this will entail a significant increase in current in the circuit and could damage your source.

You can also use more than one anode, taking, for example, several pieces of reinforcement, to increase the surface area. Anodes must be placed on different sides and connected to the plus of the source. This will be even good, since you do not have to rotate the object, and the reaction will flow evenly from all sides.

You can also restore several items at once.

All manipulations must be done only with disconnected power sources!

As all wires are connected, everything is installed - turn on our charger. We look at the ammeter. The charger should show the current flowing through the circuit.

Start surface restoration and rust removal

Immediately after power is applied, bubbles appear on the surface. A little later, a rusty shroud begins to appear. These are quite normal signs of normal electrolysis.

The reaction time depends on many factors: current, surface area of the anode and cathode, temperature of the solution, its concentration, etc.

This time can vary from half an hour to several hours, all purely individual.

You need to control the process every hour. That is, you turn off the charger, raise the cathode from objects, see how the reaction proceeded. Turn over periodically so that the restoration proceeds evenly on both sides.

Most likely the whole process will take several hours. Everything will depend on how much the item is rusted. Nothing terrible will happen if the source works more than necessary.

After use, the solution can be drained somewhere in the garden - it is not toxic. Or pour into another container and leave until the next time.

To summarize the surface restoration

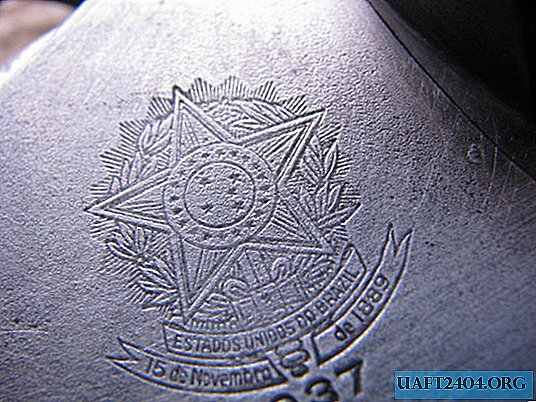

When you lift the restored item for the last time, you will notice that instead of rust, the item is covered with a black layer of chemical oxidation, such as soot. This stand must be removed. For removal it is necessary to use detergent powder type "Comet" with a hard sponge. In principle, this plaque is easily removed in a few minutes.

And voila, you resurrected your item, spending a minimum of action and money on it.

This is not magic - it is the wonders of electrolysis.

Original article in English

Share

Pin

Tweet

Send

Share

Send