Share

Pin

Tweet

Send

Share

Send

I will not say that this happens regularly, but there are a lot of cases of stud breaking during repair work in auto mechanics. And for these cases already given came up with a special tool called an extractor.

Usually they are sold in sets of various diameters, a universal repair kit, so to speak.

Each extractor has its own number.

Above on the box or inside, in the instructions, for each number its own applicable range of values is indicated. In this case, there are three lines. The highest is the serial number. Just below the initial and final size of the hole for which this extractor in inches can fit. And the last line is the initial and final thread size.

Working with such tools is straightforward. First, drill a hole in the center of the debris. Next, insert the extractor and use it to unscrew the thread fragment.

We remove the fragments of the studs with extractors

Let's move from theory to practice. I don’t have a specially broken and stuck thread, but I will do a complete imitation to visually show the whole process. I prepared a thick-walled profile with holes in which the thread is cut. I prepared bolts for these holes.

I take these bolts, with a hammer I rough the thread and wrap it with a wrench with an effort in the profile. Everything is very tight and you can’t tell me that this is not a single gram similar to real conditions.

Grinder file heads flush.

The first thing to do is to drill a hole exactly in the middle. To do this, take the core and core point, so that the drill does not jump at the beginning of drilling.

Punching point.

Now you need to drill a hole, the diameter of which should be approximately equal to half the thickness of the bolt. In this case, the M16 bolt, the diameter of the thread is 16 mm. We take a drill half half and drill a hole with a diameter of about 8 mm.

It turned out pretty evenly in the center.

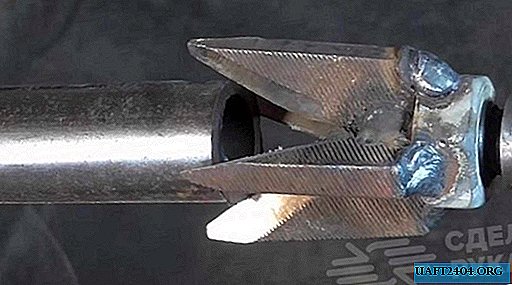

Insert the appropriate extractor and start the rotation to the left. To turn the extractor, a wrench is usually used, but if it is not there, an adjustable wrench is quite suitable.

As soon as the extractor engages, the thread fragment itself begins to turn out.

I hope it is clear. Now move on to the larger bolt. Everything is exactly the same: in the center we drill a hole.

We insert the extractor and unscrew it to the left side.

To free the tool, hold the chip in a vice or in manual clamps. And turn the key to the right side relative to a piece of thread. It is quite simple to get out.

Here is such a simple and worked out method for years.

I want to add that you should not drill a hole of too large a diameter relative to the thread, as thin walls in the stud will expand the thread itself, which will negatively affect the unscrewing.

Particular care must be taken with small diameter extractors, as they break very often.

If the chip does not want to succumb in any way, heat the assembly and sprinkle it with grease.

Share

Pin

Tweet

Send

Share

Send