These homemade clamps are very simple in terms of design and can be made from scraps of profile pipes. They are useful in the welding process - for rigid fixation of parts. To make one such clamp, you will need two segments of the profile 30x30 mm 7 cm long.

The main stages of work

From the sections of the profile, we cut out two halves of the clamp according to the template. To do this, you can use a grinder or a hacksaw for metal. In the first case it will be faster, in the second - longer, but more accurately. We connect the two halves, after which we drill holes for fastening in the "ears".

Next, a piece of 45 mm in length will need to be cut from the steel square, the edges of which must be cut at 45 degrees. Then we cut the part along in half and "build up" by welding. After that, we drill a through hole in the center for the stud.

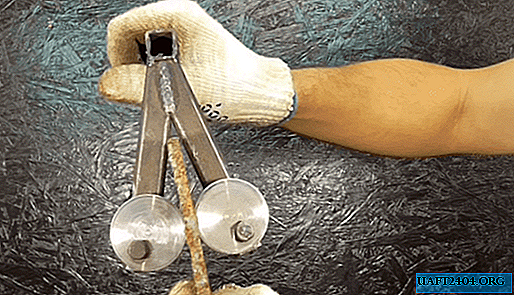

When all the main parts are ready, we proceed to the assembly. First, we connect the halves of the clamp from the profile pipe - for this, we insert a hairpin into the hole, cut off the excess and rivet the edges. Another stud must be welded to this stud perpendicularly, which we thread through the hole in the square.

We bring "marafet"

We clean the surface of the parts, grind and paint for a more aesthetic appearance. Now homemade welding clamps are ready to use. Due to their compact size, they are very convenient and will not take up much space in the workshop.