To melt a stove, fireplace, home or barbecue, you must first prepare wood chips (thin torches). Most often, this process takes even longer than chopping firewood. In addition, there is a risk of injury.

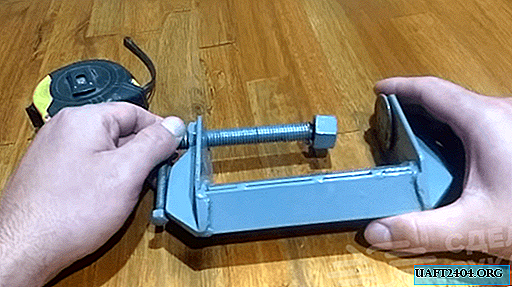

A tabletop chip made of metal scraps is a convenient and safe way to split logs (or lumber waste) into chips without using an ax. This device works on the principle of a lever.

For the manufacture of tabletop hand wood chips, a rectangular profile pipe will be required, as well as metal strips and round bars. First, we make the markup and cut off the workpieces of the desired size.

The main stages of work

From the section of the profile pipe we cut out a wedge-shaped piece with a grinder. The edges of the workpiece must be filed with metal or a petal circle to remove burrs. On one side we make a cut.

Then we drill a through hole in the profile for the mounting bolt to fix the metal strip. In the strip itself we also drill a hole. To the other ends of the strip, it is necessary to weld another segment shorter, so that a L-shaped part is obtained.

Then we cut a few more blanks from a strip of metal and collect wood chips. It will be necessary to make a base with “paws” for fixing on a table or other surface, and also sharpen a stationary cutting knife.

See the video on the website for the step-by-step process of manufacturing a desktop manual chipboard from scraps of metal.