In this review, the author shows the manufacturing process of a home-made crimping tool (more precisely, just tools) for working with cable lugs - end sleeve sleeves.

Apparently, he just decided to save on the purchase of factory crimping press tongs. Let's see what happens.

The first step is to make two parts from a piece of metal plate. Previously, it is necessary to drill two holes of different diameters in it.

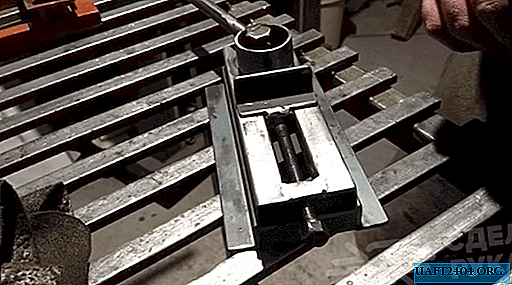

We weld the washers to the parts, and then connect them with a bolt and nut. As a result, we got a simple swivel.

The main stages of work

At the next stage, cut off a piece of the stud and weld the washer to it.

We weld an elongated nut to the top of the fixture. And in the bottom - we drill a hole. We install our hairpin, fix it with a bolt.

Take another elongated nut. You need to weld a bolt to it. Then we wind it on a hairpin. We put a heat shrink tube on the bolt.

The crimping tool is ready. And now you can experience it at work.

The author seems to have succeeded, but it is not possible to check the quality of crimping the end sleeve.

Yes, and the tip itself he put on incorrectly - on the wrong side. But maybe it was so conceived? What do you think about this homemade product?

For details on how to make a crimping tool for end sleeves with your own hands, see the video on our website.