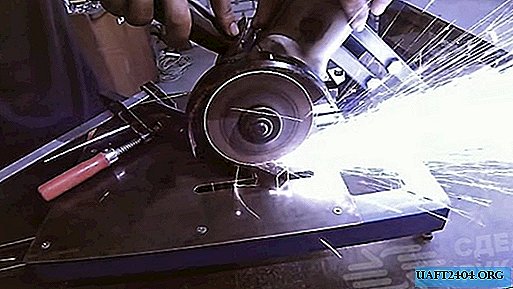

To cut smooth round holes in metal using a plasma cutter, you can use a special tool for this. It is easy to do it yourself.

For the manufacture of this homemade product you will need an electromagnet, a motor from car wipers with a gearbox, metal scraps.

The author puts on a thick washer on the motor gear sprocket, and then scalds it.

A plate with previously drilled holes is welded to this washer, and an electromagnet is already screwed to it.

The main stages of work

At the next stage, the author screwed the screws into the motor gear housing, and welded a metal plate to them.

After that, it will be necessary to cut a piece of the corner. It needs to be welded to the plate. We clean welds with angle grinder.

The corner acts as a guide. The author installs a movable mount for plasma cutting on it.

To the supporting platform (from a metal plate), the master welds a piece of a round pipe with a ring in the upper part to fix the cable.

We install the device on a sheet of metal, turn on the electromagnet and gear motor. Work is underway - we can only control this process from the outside.

For details on how to make a useful device for working with a plasma cutter with your own hands, we recommend that you look in the video on our website.