An ordinary mains or cordless electric drill is a universal tool with which you can not only drill holes in metal or wooden workpieces, but also grind them.

To do this, you will need to use a cylindrical nozzle, which can be ordered on the Internet or made by yourself. The second option is preferable, since a homemade nozzle will cost less than the factory one, and it will take very little time to make it.

Structurally, drum nozzles for a drill are very simple - they are a long rod of a cylindrical shape, on the end of which sandpaper is attached. Such a grinding nozzle is excellent for processing round holes.

The process of manufacturing a drum grinding nozzle

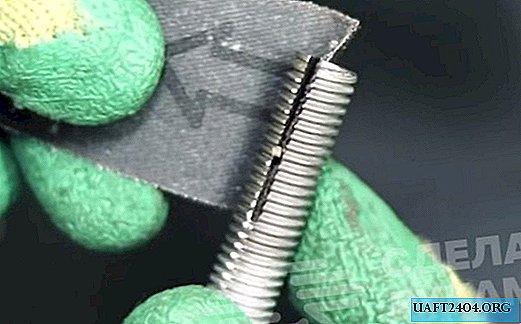

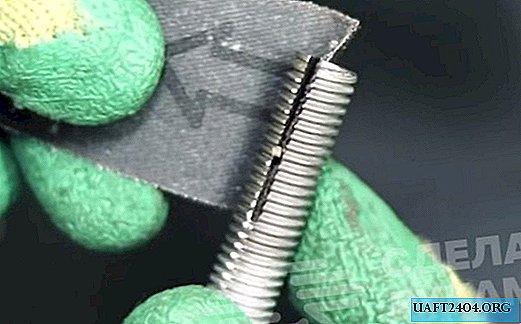

For this homemade product you will need a bolt of suitable length. First of all, we cut off the hat with the faces, and then with the help of a grinder we make a longitudinal cut about 1/3 of the length of the bolt. We clamp the pin in the lathe and grind the thread from the other end.

Thus, a shank was obtained for installing the studs in the chuck of an electric drill or screwdriver. So that it does not crank during operation, you can make it trihedral. We insert the pin into the cartridge, and at the end with a slot we wind the sandpaper of the desired grain size.

Now you can start grinding round holes in the workpieces and parts. For more details on how to make a drum grinding nozzle out of a regular bolt, see the video on the website. Write in the comments what you think about this homemade product.