For the machining of metal and steel billets, namely for cleaning the surface from traces of corrosion, paint and dirt, as well as for cleaning the welds, special disk (or flat) brush heads for electric drills and screwdrivers are used.

If you want to save on the purchase of consumables, then such brush heads for metal can be made with your own hands. To do this, you need steel washers, bolts with a nut and a steel cable. It takes no more than 5 minutes to make one home-made brush nozzle for a drill.

The main stages of work

First of all, you need to prepare the bristles for a homemade brush - for this, we unwind the steel cable and bite off pieces of about 4-5 cm in length using pliers. Then we place these pieces in a circle of the washer at the same distance from each other and fix with glue for reliability (it is better to use two-component adhesives).

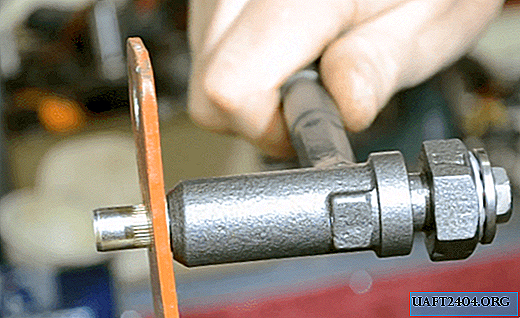

After that, we put the washer with bristles from the cable onto a bolt of suitable diameter, press the second washer and tighten with a nut. Please note that it is necessary to tighten the nut tightly, therefore, if necessary, use a vice or other improvised means. If there is a welding machine, then it is better to grab the bristles with drops of welding - it will be more reliable.

Next, we take the pliers in our hands and slightly open the ends of the cables. We install a homemade brush-nozzle for metal in a drill or screwdriver, after which you can begin to work. The process of manufacturing brushes for machining and stripping, see the video on the site.