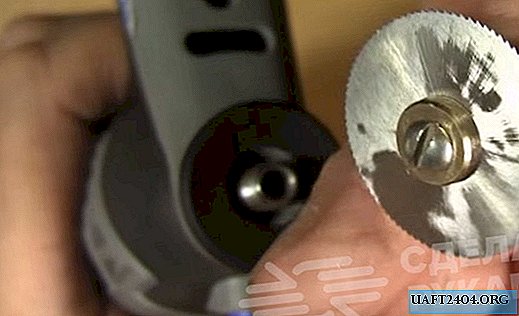

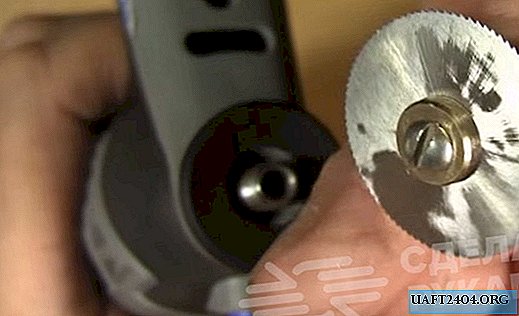

In this article, we will consider in detail how to make a home-made adapter for a disk mill for a dremel, which will be screwed directly onto the motor spindle. The adapter itself will be made of brass hexagon - this work is done on a lathe. If you don’t have a turner, you can turn to a turner for help.

The main stages of work

We clamp the brass billet in the chuck of the front headstock of the lathe, after which we drill a hole in it, bore and cut the M8 thread in increments of 1.75. It is desirable to lubricate the tap with oleic acid. We cut the workpiece of the desired length with a cutter, wind it onto the M8 tap, which we pre-clamp in the lathe holder.

We slightly cut the part, drill a hole in it and cut the M4 thread. After that, we make a special washer for the adapter from the brass hexagon. After processing the parts manually (you need to clean the surface with sandpaper, trim with a file and remove burrs), you can proceed to install the disk cutter first on the adapter, and then on the spindle of the motor dremel.

We take the adapter into our hands, put a disk mill on it, clamp it with a washer, and then tighten it with an M4 screw with a right-hand thread. Then we wind up a homemade brass adapter on the dremel spindle. The detailed process of manufacturing and installing the adapter for a small disk mill can be viewed in the video on the website.