Any home workshop begins with a table, and more precisely with a workbench. Moreover, it is desirable (for safety reasons) that the workplace be as reliable and rigid as possible, and the frame of the workbench should be made of non-combustible materials. Therefore, it is best to make a metal frame.

Workbench-transformer: stages of work

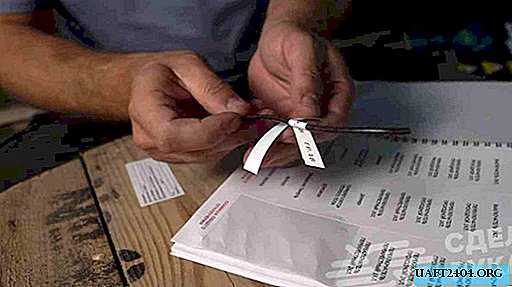

The main elements of the table will be connected to each other without using welding, since it is troublesome to cook profile pipes with a thickness of 1.5 mm, and the welding seam can ultimately turn out to be uneven. And since the home-made transforming workbench will be collapsible, then in this case it is threaded connections that are more suitable.

We mark the blanks from the profile pipe, plates and corners, according to pre-drawn drawings, drill holes for joining the main working units of the structure, and then proceed to the assembly of two halves of the workbench. When both frames are assembled, fasten the bottom of the wheel. At the last stage, it remains only to paint the frame and screw the countertop from a sheet of plywood.

To summarize

The main "trick" of this homemade workbench is that the whole structure is collapsible, which is very convenient in the conditions of cramped and limited space inside the workshop. The standard sheet of plywood has dimensions of 1520x1520 mm, and if you cut it along, you get two countertops.

Thus, it is possible to assemble a universal transforming workbench, consisting of two tables that can be installed in different ways, and as a result get either a long three-meter workbench or a large table, but of a square shape. This design is very convenient and practical to use.