To make a katana sword, you need a long piece of pipe wrench with a sponge. We heat the workpiece in the hearth and, holding it with forceps, beat it off on the anvil with a heavy hammer. Our task is to first align the workpiece, and then stretch it along and give it the desired shape.

In the handle of the sword with the help of a blacksmith hammer and a chisel we make a longitudinal groove. After hot forging, we immediately proceed to the machining of the workpiece, which is performed on a belt grinding machine. First you need to polish the ends and surface of the sword.

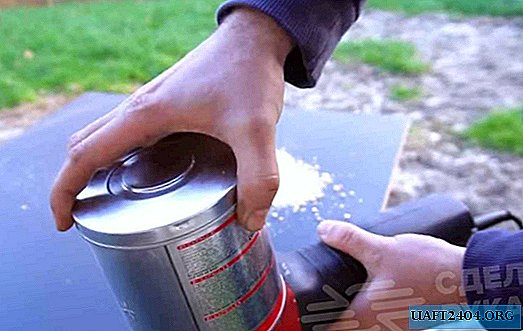

Then the blades are descended from two sides and a cutting edge is formed. After grinding, the blade must be hardened. To do this, re-heat the workpiece in the furnace and immerse it in a metal container with oil. Be careful that drops of hot oil do not get on the skin.

Katan Sword Finish

After hardening, we again proceed to grinding the surface of the workpiece. First of all, we process the blade itself, and then the hilt of the sword. This process is slow and tedious, so you need to be patient. In general, in the process of processing a katana sword, all the same operations are performed as in the manufacture of a conventional knife. The only difference is in the form of weapons.

After polishing, we proceed to polishing the surface - the katana samurai sword is considered one of the most common in Japan, and even more so has a rich history, so it should look accordingly. For a step-by-step process of forging and processing a katan sword from an ordinary pipe wrench, see the video on the site.