Today in the store you can buy clamps of any design - to perform various locksmith operations. However, if square profile pipes are available, and there is a bit of free time, then why not make a home-made clamp yourself? Of the tools for work, you will need a tape measure with a square, a welding machine and an angle grinder.

To make a home-made clamp, you will need two pieces of a 30x30 mm profile pipe of about 35 cm long (if necessary, the clamping jaws can be made larger or smaller - at your discretion). One of the sides of the profile pipes must be cut at an angle of 45 degrees.

The main stages of work

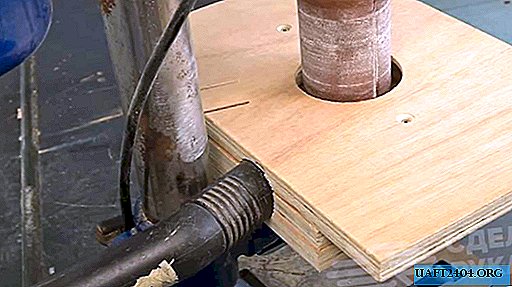

In each clamping jaw, we drill three holes: the central one for the screw, and the side holes for the guides. As a screw, we will use a long bolt, to the head of which you need to weld a knob welded from pieces of round timber.

We make guides from a steel bar of round section. When all the details of the clamp are ready, you can proceed with the assembly. We insert a bolt into the central hole and fix it with nuts. Then we insert guides into the side holes in the jaws and weld them from the upper jaw.

Nuts that secure the central screw will also need to be welded to the clamp lips. At the last stage of work, we weld a clamping penny to the upper sponge (it can be made independently or removed from the old clamp). Then we clean the welds, and the home-made clamp is ready.