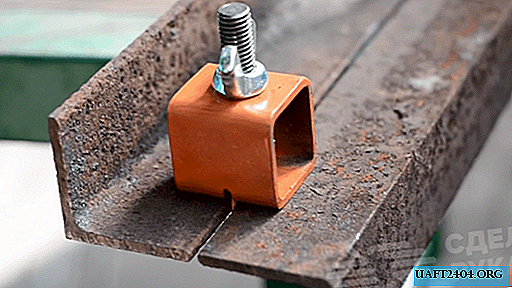

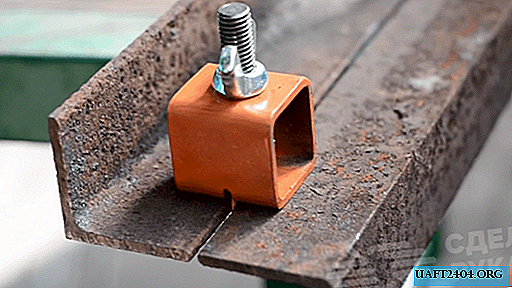

To make a simple fixture for welding, you need a section of a profile pipe 40x40 mm, a piece of a stud with a diameter of 12 mm and a length of 6 cm, as well as a steel plate with a thickness of about 2 mm and a piece of wire with a diameter of 6 mm. You will also need a screw with a nut and an M12 nut for a stud.

With this simple tool, you can set the necessary clearance between the two parts. Such home-made work is useful when welding plates, metal strips, corners, profile and round pipes. At a minimum, two such devices must be used simultaneously - they are installed along the edges of the workpieces.

The main stages of work

First of all, cut off a piece of the profile pipe of the required size, perform the markup, after which a small gash will need to be made in the marked place with the help of a grinder. On the back of the workpiece, a through hole with a diameter of 12.5 mm must be drilled.

Then, we cut out a rectangular shape from a steel plate 2 mm thick, and adjust it to the internal dimensions of the workpiece from the profile. Next, you will need to drill a hole with a diameter of 6.5 mm in this part. Using the angle grinder, a small slot is made at the end of the stud, parallel to which a gash is made from the outside.

At the next stage, a hole for the M3 screw must be drilled in the stud. We connect a piece of the plate with a hairpin, and make a similar hole in it. After painting, assembly is carried out.

For a detailed process of making a homemade welding fixture, see the video on the site.