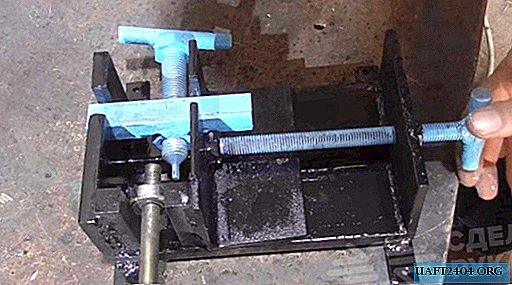

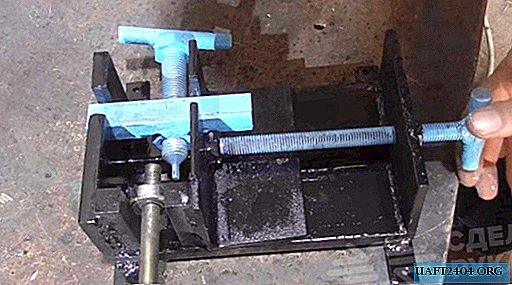

The main difference between this puller and the classic devices for dismantling bearings is that it can be used stationary by installing it on the table surface. At the same time, a universal puller allows you to remove bearings and gears of different diameters from the shaft.

To make such a device, as always, simple and affordable materials will be required. And therefore, this homemade product, in spite of some cumbersomeness and constructive “clumsiness,” fully justifies itself.

To make a homemade bearing puller, you need two thick plates, a piece of a rectangular plate, a corner and a piece of steel square. An angle grinder, an electric drill and a welding machine will need to be prepared from the tool.

The main stages of work

First of all, the master prepares the necessary work pieces. In a piece of corner you need to drill three holes and make a wide slot with a grinder. Also, the slot must be made in a piece of metal of a rectangular shape.

Then the master welds the corner to a piece of square bar. After that, it will be necessary to weld a piece of metal with a slot to thick plates (on the edge) - opposite the steel corner. After that, the master cleans the welds with an angle grinder and removes the paint from the plates.

At the last stage of the work, the remaining parts are manufactured and welded to the main structure. At the end of the stud on the lathe, the master makes a "nose" - it will abut against the shaft on which the bearing is mounted.

For details on how to make a universal desktop bearing puller with your own hands, see the video on the website.