Share

Pin

Tweet

Send

Share

Send

The main materials:

- compressor from the refrigerator;

- steel shaft, with a diameter for the compressor piston or smaller;

- channel 27 mm;

- corner 25x25 mm;

- profile pipes 40x20 and 20x20 mm;

- rod d8 mm;

- clamping spring;

- nut with lamb M8;

- 2 M8 nuts;

- plastic bottle 2 l;

- Chipboard;

- 2 bolts with M6 washers.

Electric jigsaw assembly

The compressor has an external casing covering the engine. To get to his motor, you need to cut the body along the factory weld. An electric motor with an open piston is removed from the casing.

The motor needs refinement in the form of a mount for attaching a nail file to the piston. To do this, the top of the piston is ground with a file, and a hole is drilled in its center. Since it is very thin, simply cutting the thread in it will not work.

Prepared piston must be removed. Since the compressors from the refrigerators are not designed for repair, their dismantling is not structurally provided.

To knock out the piston pin, you will have to drill a balancer.

For the extracted piston, an extension is made of a steel shaft of suitable diameter. A spike is pierced on the shaft, which fits tightly into the drilled bore of the piston. It is necessary to weld a fungus on the pressed-in spike on the inside of the piston. The result is an improvised rivet that does not allow the parts to come apart.

The machine bed is made of a channel. To attach the engine to it, a mount of 2 pieces of a corner of 25x25 mm is used. They are marked under the mounting holes of the electric motor, drilled and, if necessary, grind.

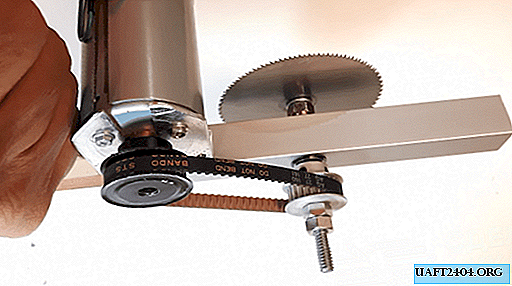

The corners are screwed to the engine using bolts removed from the compressor. Next, you need to install the previously removed rotor with a crank. A lubricated piston is inserted into them, to the shaft of which an eye is additionally welded to press the file.

The assembled engine is exposed in the center of the bed and welded to it around the corners. It does not hurt to weld a small piece of the shaft on the counterweight of the compressor to compensate for the weighting of the piston. This will reduce vibration during operation.

From the profile 40x20 mm and 20x20 mm the L-shaped upper lever of the machine is brewed, as in the photo. In the 20x20 profile, a hole is drilled opposite the piston. To each side you need to weld an M8 nut.

Hold and tighten the jigsaw file will be polished rod d8 mm. Grinding will reduce its diameter by a fraction of a millimeter to prevent friction on the bushings. An ear is welded on one end to tighten the web, and a thread is cut on the other. The rod is inserted into the hole of the L-shaped lever and is pressed by the wing nut through the spring. Also, a frame under the machine table is made from a 20x20 mm profile. In the ears of the piston and the rod, the ends of the nail file are clamped with M6 bolts.

The design already has the shape of a finished jigsaw, but motor protection from sawdust is required. On it you can build a casing with a cut plastic bottle.

A tabletop made of chipboard is screwed onto the frame of the machine table, with a previously made slot for a nail file.

The assembled jigsaw has enough power to cut laminate flooring, lining and even bars. The proposed design retains the possibility of modernization. You can modify the table to raise it when the teeth of the nail file are erased, add a protective screen or backlight.

Share

Pin

Tweet

Send

Share

Send