Share

Pin

Tweet

Send

Share

Send

Note: Our material relates to a purely technical topic. The legality of making design changes is the topic of another article.

So, consider a typical set of electronic add-ons with tuning elements:

- automatic daytime running lights;

- video recorder that turns on with the engine;

- pneumatic signal powered by an electric compressor.

If you are familiar with the electrical part of the car, you probably know that any consumer (headlights, starter, fans, power windows) is switched on using a relay. This is convenient from a control point of view, and allows you to separate the thin signal wires from thick power cables. To connect newly installed devices, we assemble a new relay unit.

First, let's analyze the scheme

The operation algorithm is as follows: when starting the engine, daytime running lights should light up and the recorder will turn on. After the engine is turned off, these devices turn off. In addition, DRLs should go out when the dimensions or head light are turned on: this is what technical regulation requires.

For implementation, you will need three standard automotive relays with 5 contacts (sold in the car shop). The diagram is indicated by the numbers 1, 2 and 3.

1. Green wire - power. 12 volts through a fuse are constantly supplied to contacts No. 87 (normally open) of relays 1 and 3. Output contacts No. 30 are connected to the positive inputs of the recorder and navigation module. The negative wire (ground) can be connected to the car body at the installation site of the devices.

2. The red wire in the circuit supplies the control voltage of 12 volts, which appears after the engine starts (or turns the ignition key). In automobile circuits it is designated as "HOT RUN". There are a lot of connection points: from the radio to the power of the fuel pump. The signal is easy to find in the description of your car.

3. When 12 volts appear on the red wire (contact No. 85), relay coils 1 and 3 are activated, the supply voltage through the green wire includes the recorder and DRL (contacts No. 87 and No. 30 are closed).

4. On relay 3, the control voltage is supplied through normally closed contacts No. 87a and No. 30 of relay 2. When voltage is applied to contact No. 85 of relay 2, the coil is activated and stops supplying control voltage to relay 3. The control signal comes from the included side lights: DRL goes out, and the registrar (through relay 1) continues to work.

The circuit can be upgraded by adding manual control. This will require three-position switches with three pairs of contacts.

With this connection method, you can control the relay unit manually. In the “OFF” mode (middle position of the switch), the circuit is disabled. The "AVTO" mode starts the recorder and DRL when the motor starts. In the "ON" position, you can turn on the equipment with the engine turned off:

- for example, a registrar for monitoring a car in a parking lot at a supermarket;

- or illuminate the garage door with running lights, not including the head light.

Tools and materials

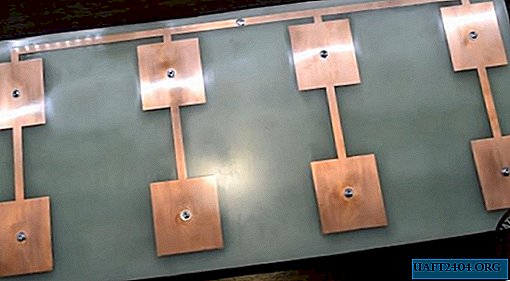

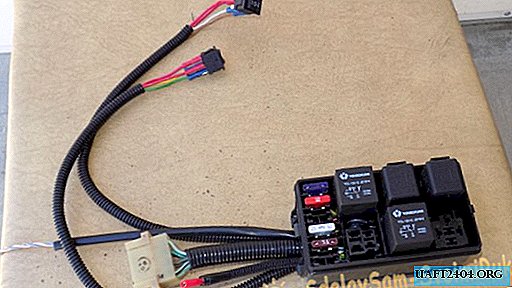

1. For the implementation of the project, on aliexpress a box for 6 relays and 6 fuses was purchased, complete with contact groups.

2. Switches, button for pneumatic signal, crimp contacts, automotive relays.

3. Wires, cambrices, automobile corrugation.

4. Side cutters, pliers, insulation stripping kit (KSI), soldering iron, electrical tape, thermo crimping cambric.

Step-by-step installation process

Before starting work, it is advisable to print a detailed wiring diagram with reference to your car: with color coding of wires, points of connection to power. It is necessary to mark the contacts, otherwise assembly errors may occur. The diagram adds relay No. 4 with a pneumatic signal enable button and a front parking sensor.

Important! External connection may vary depending on the brand of car.

1. We carry out the wiring of wires and connectors for the relay according to the diagram.

2. The wires will inevitably cross, with good insulation this is not a problem.

3. Crimping the contacts is done mechanically, the soldering iron is not used.

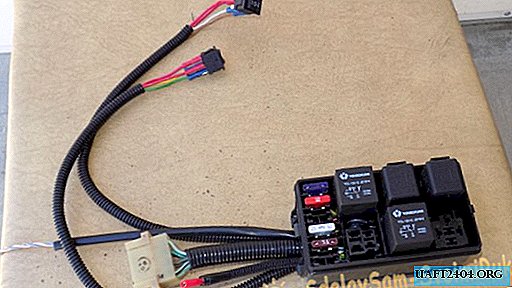

4. After connecting all the wires, form the bundles and lay them in the corrugation.

5. It is convenient to use a ready-made connector for connecting control and supply wires: in this case, from the VAZ classic steering column switch.

6. If the relay unit is installed under the hood, it must be closed with a standard cover. For cabin installation this is not necessary.

7. We connect the switches using crimp connectors.

8. We assemble a test circuit to verify the installation (of course, outside the car and with an input fuse). We simulate all modes.

Installation of wires inside the car

Power can be taken directly from the battery terminal, through the fuse. Or find a switching point in the standard fuse box (you need a diagram of your car).

Important! This aliexpress box has input fuses for each line.

All additional wiring is performed in the corrugation, mounted on the body with ties.

Through the standard openings in the engine shield, the harness starts up in the passenger compartment.

Inside the cabin, the cable also fits into the corrugation, and is attached to the structural elements.

All connections are made by soldering, insulated with a thermokebric and again into the corrugation.

For quick connection, you can use quick-detachable connectors (from the same aliexpress).

The signal from the dimensions does not have to be taken near the headlights. It is enough to make a tap (by soldering) from the connector of the light control unit.

Set the switches (buttons) in the cabin. We select the elements of the panels, without violating the design.

Switches should be accessible and subtle: for example, in niches for small things.

All wires are connected using removable contacts: for ease of dismantling when disassembling the passenger compartment.

As a result, the control and supply wires with contact sockets are concentrated in the place of installation of the relay unit.

We carry out a test inclusion according to the scheme, we check the operability.

In this case, the relay unit is installed in the floor console between the driver and the passenger. The mounting location is individual for different cars. For fixing, brackets can be made.

Check the fuses in the block.

We finally fix the module in the console.

We disconnect the long wires from the switches, set the switches to a niche, assemble them back.

Pneumatic signal connection

It is included separately from the standard horn by a button on the control panel. To start a powerful compressor, a relay is installed (in the diagram: No. 4). The signal itself is mounted on a frame element or underbody protection.

Wiring neatly fits in the engine compartment.

The corrugation is lowered to the installation site, the supply wire is connected to the pneumatic signal compressor.

Why through the relay? A direct connection will melt the signal button after 10 presses: the air compressor current is about 15 amperes.

Important: Direct power connection (using the vehicle's standard fuses) is undesirable. In the event of a short circuit, you can de-energize important components of the electrical circuit.

Any additional device is connected through its fuse.

Share

Pin

Tweet

Send

Share

Send